My 100% record of working on parts that are slightly too big for my tools remains unbroken.

2.5mm cutter. I couldn't get a short one, but it's not like there will be much cutting force on this job.

Making the first hole.

Checking that the hole position is roughly correct.

Looks OK, so make the rest of the holes.

Everything lines up nicely.

The PCB now lies flush with the base.

The world's cutest flap wheel, used to roughen the mating surfaces and improve the adhesive's grip.

There's a nice mixture of phenolic/paper base, epoxy/fibreglass PCB, copper conductor, and who-knows-what solder resist for the adhesive to bond to.

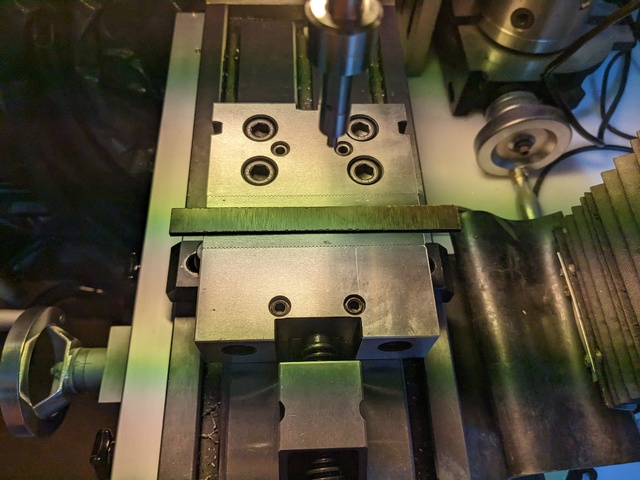

Trying out a setup for curing the adhesive. This is almost the silliest arrangement of parallels I've ever used.

Epoxy applied. This is far too much, which is my usual mistake with two-part adhesives. Even half of this would have been too much. It's also a better idea to put the adhesive on the smaller of the two parts.

The epoxy takes 24 hours to cure. Why yes, I did end up scraping the stuff off the parallels and vice jaws.

The next day, with the adhesive now cured, it's time to trim the oversize base (and excess adhesive) to make everything flush with the PCB. The cutter is the same 12mm WC one I use for aluminium and anything at least as soft.

Trimmed to match the PCB. I eyeballed this to roughly the correct depth, then took 25μm passes until the last of the adhesive vanished.

Trimming the end faces.

With all four faces trimmed the part looks and feels like a single piece.

I ran the cutter the wrong direction on one side, causing these small delamination defects. Fortunately this is a trial run before making the production parts.

3.5mm cutter. This time I could get a shorty.

Clearing the adhesive out of the slots, and extending them through the base. I also eyeballed the alignment here.

I held the cutter a little too deep in the collet, so the collet clamping nut rattled against the blade terminals just as the cutter reached the base of the slots. The noise made me think I'd accidentally cut into a parallel or the vice jaws.

The completed part.

How the part will be mounted in use.