The epoxy is cured. I need to clean up a few places it shouldn't have gotten.

This is the scariest clamping I think I've ever done. Too little and the part will come flying out. Too much and it will crush, or bow out, or just plain snap.

The cover is 20mm wide, slightly too large to fit in the 19mm gap between the LED riser blocks on the panel.

A slight rebate solves this.

Which of course should have been 0.5mm on each side for 1mm total, not 1mm per side. But this will be almost invisible in use.

Now I need to make the square hole. I had hoped to clamp the cover this way up so the sides had some support from the parallels, but I can't get close enough to the flip-up cover.

Stop screwing around and fit the vacuum system, episode 342.

After cleaning up the chips I found the part had lifted slightly, probably because I was too scared to clamp it harder.

Making 1mm holes for the pins that will hold the cover to the panel. They might be tight enough as a press-fit, but I'll probably use adhesive too.

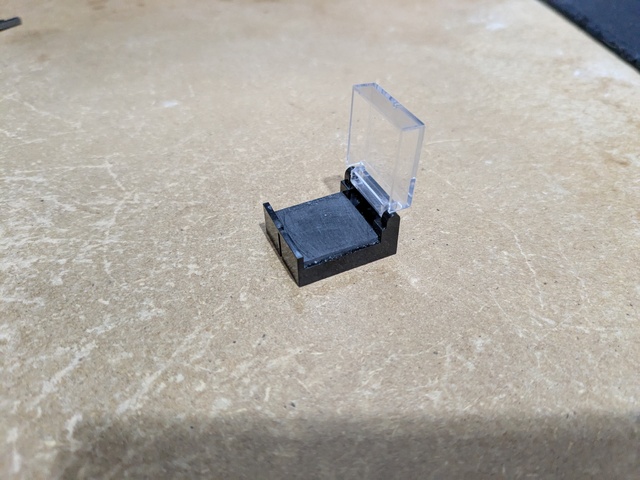

Doesn't look too bad.

It would be nice if I had moved the two covered switches a little off the standard spacing to allow more room for the cover, but it works OK.

For the second part I removed the bulk of the material by drilling an array of holes, hoping that by making most of the force downward the part would be less likely to move in the vice.

Two completed parts. The metal panel still needs some countersinks added before I can install the quarter-turn fasteners and paint it.