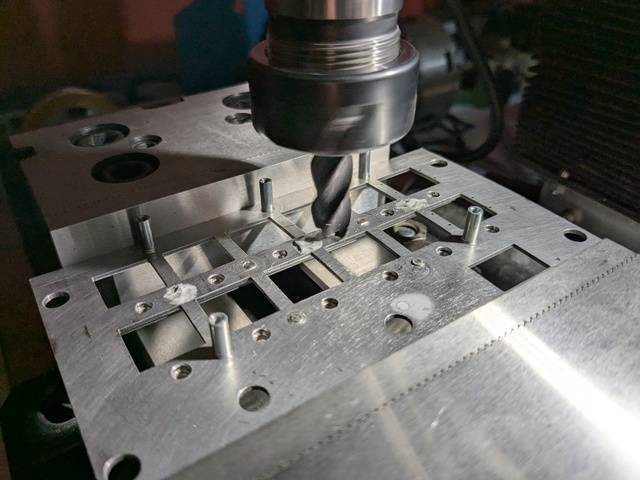

I filled the accidental holes with alloy wheel repair resin (I think it's polyester), and am now milling the excess off.

It's like they were never there! Fortunately this will vanish under the paint and the customer doesn't see this side in normal use anyway.

I've added the annoying 100° countersink to the holes and put the fasteners in place.

Using my "press" to crimp? Swage? Cold forge? Something like that.

The fasteners are now secure, and the deformed metal is slightly recessed as it should be.

The customer's view.

As expected, the thin wall on one side of the hole bowed out a little. Amusingly I've seen this same defect on the professionally made panels I'm replacing. If there is a next time I'll make the panel slightly too wide, fit the fasteners, then mill it to final size.